The modern broiler chicken slaughter process is a detailed series of steps. It ensures animal welfare, food safety, and efficiency. This overview covers the key stages from arrival to final packaging and shipping.

The journey starts with humane transport and handling of the chickens. Trained workers guide them calmly through the facility. This focus on animal welfare is crucial for the next steps.

In the U.S., electrical stunning is the main method used. Some places use controlled atmosphere stunning (CAS) systems too. These methods make the chickens unconscious and pain-free before slaughter.

After stunning, the chickens go through various stages. These include feather removal, evisceration, and carcass cleaning. Throughout, they are inspected and tested for food safety and quality.

The last steps involve packaging, labeling, and shipping. The industry also focuses on employee safety, especially during the COVID-19 pandemic.

Key Takeaways

- The broiler chicken slaughter process in the U.S. is primarily focused on electrical stunning as the primary method of rendering chickens unconscious prior to slaughter.

- Controlled atmosphere stunning (CAS) systems, using gases such as carbon dioxide, are used in a limited number of facilities.

- The industry’s commitment to food safety is evident in the more than 300 safety checks conducted on each piece of chicken throughout the processing cycle.

- Chicken products are labeled with the date packaged, USDA seal of approval, and the establishment number for traceability.

- Retail products are typically delivered to a retailer’s warehouse the day after leaving the production plant, ensuring freshness.

Introduction to Broiler Chicken Slaughter

The slaughter of broiler chickens is a detailed process. It focuses on animal welfare, food safety, and quality. This section will explain the key steps of the broiler chicken slaughter process.

Broiler chickens grow fast and are ready for slaughter at about 8 weeks. They weigh around 5 pounds on average. The process is regulated and uses advanced technology to ensure it’s humane and efficient.

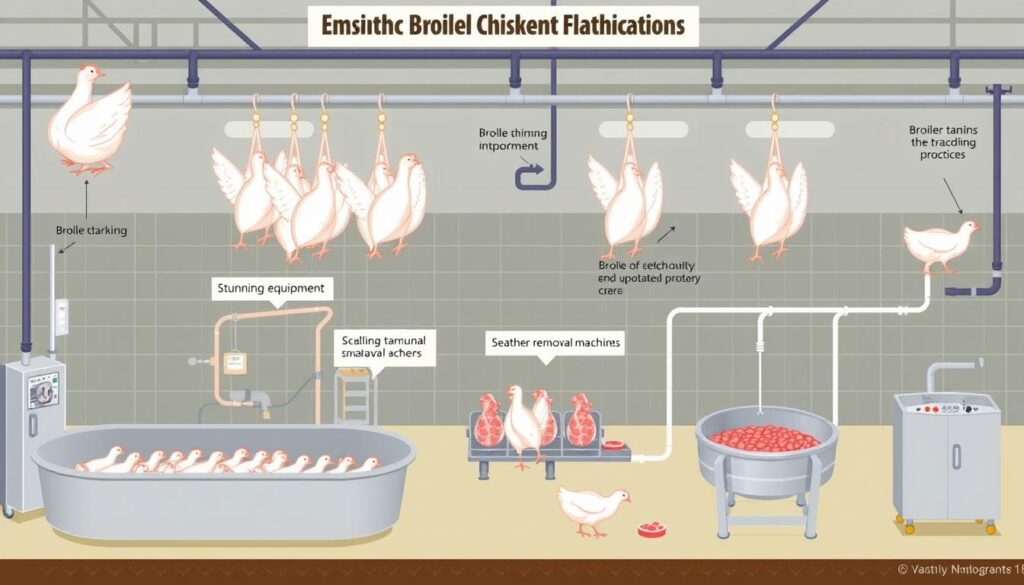

Every step of the broiler chicken slaughter process is designed to protect animal welfare and food safety. Let’s look at the different stages:

- Arrival and Handling at Processing Plant: Broiler chickens arrive at the plant calmly. Trained workers handle them gently.

- Stunning Methods: Various stunning methods are used. These include electrical waterbath stunning and controlled atmosphere stunning. They make sure the birds are unconscious before slaughter.

- Slaughter Process: The slaughter is done with great care. It follows strict protocols to ensure food safety and quality.

- Feather Removal and Evisceration: The birds are scalded and plucked. Their internal organs are then removed in a clean environment.

- Cleaning, Chilling, and Inspection: The carcasses are washed, chilled, and inspected by the USDA. This ensures they meet safety and quality standards.

Understanding the broiler chicken slaughter process shows the industry’s commitment. It ensures a reliable and high-quality poultry supply.

“The broiler chicken slaughter process is a testament to the industry’s dedication to animal welfare and food safety, ensuring a consistent and reliable poultry supply for consumers.”

Arrival and Handling at Processing Plant

Broiler chickens are carefully moved from the farm to the processing plant. This journey is short, usually under 60 miles. It helps reduce stress from long trips.

Rested and Calm Transportation

When they arrive, the chickens are calm and rested. “Rub bars” in the transport modules soothe them. Low lighting also helps keep them calm.

Humane Handling by Trained Workers

Workers trained in humane handling greet the chickens. They gently hang the chickens by their feet on a moving line. This makes the transition smooth and stress-free.

The chickens arrive calm and rested, thanks to careful transport and handling. This focus on animal welfare is key. It ensures the chickens are treated with care and respect.

Stunning Methods

In the broiler chicken slaughter process, stunning methods are key for a humane and painless transition. The main technique used in the United States is electrical stunning. It makes the birds unconscious and pain-free before slaughter. This method works well, with 99% of birds being totally unconscious after the stun.

Electrical Waterbath Stunning

Electrical waterbath stunning is used worldwide for poultry slaughter. But, it has raised big animal welfare concerns. The European Food Safety Authority advised against it in 2012.

Head-Only Electrical Stunning

Head-only electrical stunning systems are being developed. They aim to control the electrical parameters each bird gets. This could help solve some welfare issues with the waterbath method.

Controlled Atmosphere Stunning

Gas stunning is not common in Europe or the United States. Yet, controlled atmospheric stunning (CAS) is seen as humane and acceptable. The American Association of Avian Pathologists and the American College of Poultry Veterinarians support it. The U.S. industry might stick with electrical stunning but is open to new technologies for animal welfare and quality reasons.

| Stunning Method | Usage in U.S. Broiler Chicken Slaughter (2019) |

|---|---|

| Electrical Stunning | 92% |

| Controlled Atmosphere Stunning (CAS) | 7% |

| No Stunning | 1% |

“The United Nations World Organization for Animal Health (OIE) guidelines on humane slaughter cover electrical stunning and controlled atmospheric stunning (CAS) without expressing a preference for one method over another.”

Slaughter Process

The broiler chicken slaughter process is quick and efficient. It aims to minimize discomfort for the birds. The main method is a single cut to the throat of an unconscious bird. This is usually effective in causing a swift and humane death.

However, trained workers are always ready to quickly euthanize any birds that might not die right away. This is a safety measure to ensure all birds are treated humanely.

Keeping the equipment in good shape is key to a fast and humane slaughter. This means regular sharpening and checks on the blades. It also means having a team of skilled people ready to step in if needed.

By using technology and careful human oversight, the industry aims to keep animal welfare high. This is the goal of the broiler chicken slaughter process.

“Technology makes slaughter extremely quick to minimize discomfort. While making a single cut to the throat of an unconscious bird is largely effective, should the blade miss for any reason, trained workers stand by to quickly euthanize remaining birds.”

The goal is to ensure a fast and humane end-of-life for the birds. The industry uses advanced technology and strict equipment care. They also have trained personnel to improve the slaughter methods for broilers.

Feather Removal and Evisceration

After the broiler chickens are killed, the process of removing feathers and evisceration starts. This stage is key to getting the birds ready for further steps.

Scalding and Plucking

The feather removal journey begins with scalding. The chickens are dipped in hot water to loosen their feathers. The water’s temperature is carefully set to get the right skin color and texture.

Next, the chickens go through a mechanical feather-picking machine. This machine, with hundreds of rubber “fingers,” removes the feathers efficiently.

Organ and Feet Removal

After the feathers are gone, the chickens go to the eviscerating line. Here, their internal organs and feet are carefully taken out. This makes the carcass ready for cleaning, chilling, and checking.

The automated evisceration lines can handle up to 70 birds per minute. This shows the industry’s focus on being efficient and productive. The organs and feet are then sorted into edible and inedible parts, showing how resources are used well.

The broiler chicken slaughter process doesn’t stop there. It includes more inspections, washing, and chilling to ensure food safety and quality.

An Overview of the Broiler Chicken Slaughter Process

The broiler chicken slaughter process is complex and well-organized. It aims for efficiency, food safety, and animal welfare. Every step, from arrival to shipping, is watched closely to meet top standards.

Using the whole bird is key, reducing waste and saving resources. Chicken feet are a treat in Asia, and feathers become animal feed.

The process starts with humane bird handling. This ensures birds are treated with care and less stress. Electrical waterbath stunning is common in the U.S., while controlled atmosphere stunning is growing for its animal-friendly benefits.

After stunning, birds are quickly and humanely killed. Then, feathers are removed and the insides are taken out. The cleaned carcasses are chilled and checked by the USDA for safety and quality.

Employee safety and microbiological tests are crucial. They make sure the final product is safe and meets consumer expectations. The broiler chicken slaughter process shows the industry’s dedication to ethical and sustainable practices.

Cleaning, Chilling, and Inspection

After removing organs, broiler chicken carcasses are cleaned thoroughly. This ensures food safety and quality. They are washed and sometimes rinsed with organic substances. These are regulated by the USDA and FDA to meet food production standards.

Next, the chickens are chilled to keep them fresh. Quality and food safety teams inspect each bird. They check for quality, safety, and wholesomeness, following strict rules.

Carcass Washing and Rinsing

The chickens are washed and rinsed to remove bacteria. This step is crucial for food safety. The substances used are approved by the USDA and FDA for food production.

Chilling and USDA Inspection

After cleaning, the chickens are chilled to stay fresh. Before chilling, they are inspected by quality teams and USDA inspectors. These checks ensure the chickens meet quality and safety standards.

A USDA inspector also checks every inch of each chicken. They look for disease, fecal matter, or bruises. This detailed inspection is key to ensuring the chicken’s safety and quality.

Microbiological Testing and Processing

In the broiler chicken processing industry, food safety is key. After chilling, chickens undergo strict microbiological tests. These tests are done by companies and the USDA to find harmful microorganisms like Salmonella.

While the industry works hard to keep these microorganisms away, it’s also up to consumers. They must follow proper handling and cooking steps. Chicken is safe to eat when it reaches 165 degrees Fahrenheit (74 degrees Celsius).

There’s a push for better microbiological testing of broiler chickens. This includes using PCR or LAMP technology for faster testing. These methods help improve food safety measures in broiler chicken processing.

“Salmonella has an infectious dose as little as 15-20 cells, while the infectious dose for Campylobacter for food poisoning is as few as 500 cells.”

Keeping poultry meat safe is a big challenge. The industry stays focused on keeping consumers safe. By working together, everyone can ensure top food safety in the broiler chicken industry.

Packaging and Shipping

The last step in making broiler chicken is packaging and shipping. After checking, chilling, and cutting, the chicken is ready to go. It’s sent to stores, restaurants, and other places.

Cut-Up and Tray Packing

Broiler chicken carcasses can be turned into different packaging options. This includes fresh or frozen chicken for stores, chicken for restaurants, or even exports. You can find “tray-pack” items like drumsticks, thighs, and wings in stores.

Labeling and Metal Detection

Before loading, trucks and trailers are checked for working order and cleanliness. Once loaded, the trailer is sealed to keep everything safe. The chicken usually arrives at stores the next day.

Quality control and food safety are key during packaging and labeling. This ensures the chicken is safe and of high quality for consumers.

“Maintaining an unbroken cold chain for fresh chicken is crucial to keeping the meat below the danger zone of 4.4°C (40°F), highlighting the importance of temperature control in ensuring product quality and safety.”

The USDA and FDA watch over the chicken’s safety and quality. They check temperatures, look for contaminants, and check labels. This helps keep the chicken fresh and safe for everyone.

Employee Safety Measures

Keeping employees safe is a big deal for the broiler chicken processing industry. Every poultry company works hard to protect its workers. This lets them keep making safe, affordable, and quality chicken for us.

Because of COVID-19, these companies have added more safety steps. They want to keep their employees healthy.

Poultry processors follow the CDC and local health guidelines closely. They also talk to infectious disease experts. This helps them create safety plans that fit their places.

Comprehensive Safety Protocols

The broiler chicken processing industry has always put employee safety first. In the last 30 years, injuries and illnesses have dropped by 75%. In 2022, the rate of illnesses and injuries was 5.7 per 100 workers, down from 22.7 in 1994.

| Metric | Value |

|---|---|

| Poultry Processing Injury Rate (2022) | 5.7 per 100 full-time workers |

| Poultry Processing Injury Rate (1994) | 22.7 per 100 full-time workers |

| Poultry Processing Injury Rate vs. Other Agricultural Industries (2022) | Lower than 6.5 per 100 full-time workers |

The Broiler Chicken Industry Safe Work Practices (BCISWP) started in 2011. They help make the industry safer. These practices are supported by many groups and help manage health and safety.

Employers in the poultry industry must teach and enforce these safe practices. They keep improving these practices to keep the workplace safe and healthy.

The broiler chicken slaughter process focuses on treating animals humanely, ensuring food safety, and maintaining quality. From the chickens’ arrival to the final product’s packaging and shipping, strict rules are followed. This ensures the highest standards are met.

Understanding the process’s stages is key. This includes how chickens are handled, stunned, and slaughtered. It also covers feather removal, cleaning, chilling, testing, and packaging. This knowledge shows the care and safety measures in place for safe, quality poultry.

The industry’s goal is to follow humane slaughter principles. This ensures animal well-being and the safety and quality of the products. As the industry grows, being open and ethical is vital. This meets the needs of today’s consumers who care about their food’s origins and treatment.

By learning about the broiler chicken slaughter process, we can make better choices. This helps improve animal welfare and food safety. It’s a step towards a better future for all.