The grower phase is a key part of broiler chicken life. It comes after the starter phase. In this stage, chickens grow a lot and get stronger. They also develop better digestion, immunity, and feathers to keep warm.

It’s important to manage their care, food, and environment well. This helps them grow to their best. Knowing about the grower phase is crucial for raising chickens on a large scale.

Key Takeaways

- The grower phase is a crucial stage in broiler chicken production, following the starter phase.

- Broiler chickens go through significant physiological changes and growth during the grower phase.

- Proper management, feeding, and environmental control are critical to ensure birds reach their full potential.

- Understanding the grower phase is essential for successful commercial poultry farming.

- Broiler chickens must develop a stronger digestive system, immune function, and feathers for temperature regulation during the grower phase.

Understanding the Grower Phase in Broiler Chicken Production

The grower phase in broiler chicken production is a key stage. It starts after the starter phase, around 3-5 weeks old. During this time, chicks grow their digestive system, immune function, and feathers.

It’s important to manage, feed, and control the environment well. This helps the birds grow fast and reach their best.

Broiler chickens have different growth stages. The starter phase is from hatch to 3-5 weeks. The grower phase is from 3 weeks to 6-8 weeks, when they’re ready for processing.

It’s crucial to pay close attention to the chicks’ needs in the grower phase. This ensures they grow healthy and reach their full potential.

| Growth Stage | Age Range | Key Characteristics |

|---|---|---|

| Starter Phase | Hatch to 3-5 weeks | Chicks develop their digestive system and immune function |

| Grower Phase | 3 weeks to 6-8 weeks | Chicks develop feathers for temperature regulation and continue rapid growth. |

In the grower phase, it’s vital to watch the chickens’ growth closely. Make sure they get the right nutrients and have a good environment. By understanding their needs, poultry farmers can improve production and help the birds reach their best.

Broiler Chicken Growth Stages

Broiler chickens go through three main growth phases: starter, grower, and finisher. Knowing these stages is key to managing their growth well. It helps in making sure they grow and perform their best.

The Starter Phase

The starter phase starts from when they hatch to 3-5 weeks old. It’s a vital time for chicks to develop their digestive and immune systems. They also start growing their feathers during this phase.

The Grower Phase

After the starter phase, broilers move into the grower phase. This lasts from 3-5 weeks to 6-8 weeks old. They keep growing, and their systems keep improving. Good care and food are crucial during this time.

The grow-out stage starts at 11-16 days old and goes until they’re ready for processing. Feed is a big expense in raising broilers, costing about $0.31 per pound of meat in 2012.

Soybean meal is a main protein source in poultry feed globally. It’s great for chickens’ amino acid needs. Water use varies by age and temperature, as shown by Leeson and Summers.

“Understanding the growth stages of broiler chickens is crucial for effective management and optimization of poultry production.”

Feeding Broilers During the Grower Phase

Feeding broilers right during the grower phase is key to their success. Broiler feed has 18-24% protein, more than other poultry feeds. This helps with muscle growth and overall growth. The grower phase, from 17 to 37 days, is when broilers grow fast and reach their target weight.

Choosing the Right Starter and Grower Feeds

Broiler producers often use a mix of starter-grower feed. Starter feed is for young chicks from day one to 17 days. It gives them the nutrients they need for a strong start. Then, grower feed helps adolescent broilers grow and develop muscles.

Medicated Chick Feed Options

Medicated feeds, like those with Amprolium, are used in the starter and grower phases. They help the birds’ immune system and prevent coccidiosis. These feeds keep broilers healthy and thriving during their early development.

Choosing the right feed and managing it well is crucial for broilers to grow well. A balanced diet with protein, vitamins, and minerals helps them grow fast and efficiently. This improves their overall performance.

“Investing in high-quality broiler feed leads to rapid growth and improved meat quality, making broiler production more economically viable.”

Keeping a regular feeding schedule and using tools like the 123POULTRY app are important. Also, making sure they have clean water is key. Water intake affects feed consumption and growth.

Understanding the grower phase and good feeding practices is vital. They help broilers reach their full potential. This success is important for the broiler operation’s success.

Poultry Farm Management

Effective poultry farm management is key to success in broiler chicken production. The type of farm, whether pullet, breeder, or broiler, affects management and biosecurity. Daily tasks also vary.

Pullet farms raise young laying hens for egg-laying duties. Breeder farms manage hens and roosters for hatching eggs. Broiler farms focus on raising meat birds from chicks to market-ready.

Growers work with integrator field technicians to follow specific practices. This teamwork ensures the health and productivity of the birds.

Broiler Farm Management Practices

- Strict biosecurity protocols, including foot baths and sanitization procedures, to prevent disease transmission

- Careful monitoring of environmental conditions, such as temperature, humidity, and ventilation, to create an optimal growing environment

- Diligent feed and water management to ensure birds have access to the necessary nutrients and hydration

- Proactive health management, including vaccinations and disease prevention measures

- Efficient litter management to maintain a clean, dry, and comfortable living space for the birds

- Detailed record-keeping to track the performance and progress of each flock

| Poultry Farm Type | Key Management Focuses |

|---|---|

| Pullet Farm | Rearing young laying hens, preparing for egg production |

| Breeder Farm | Managing both hens and roosters to produce hatching eggs |

| Broiler Farm | Raising meat birds from chicks to market-ready birds |

By following a detailed management plan, growers can improve their flock’s health and productivity. This leads to a successful broiler chicken production operation.

Broiler Nutrition Requirements

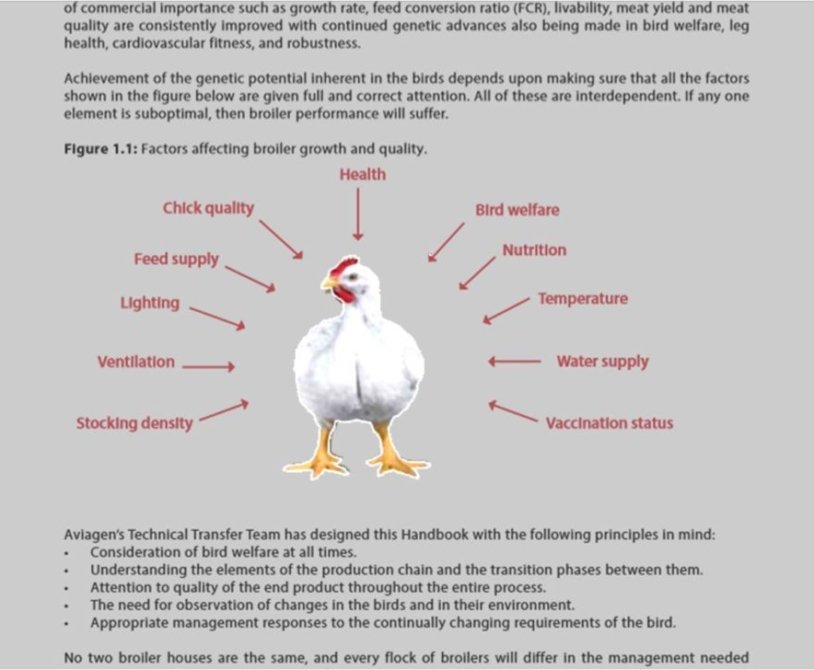

Broiler chicken nutrition is key to successful poultry farming. These birds need a balanced poultry feed composition for fast growth. Corn and soybean meal are the main ingredients, offering carbs, protein, and amino acids.

Poultry nutritionists carefully mix broiler rations. They aim for live weight gain, feed conversion ratio, and the right carcass composition.

Broilers’ nutritional needs change over time. Feed composition is adjusted to meet these changes. Supplements like synthetic amino acids, enzymes, vitamins, and minerals are added. This ensures birds get all the needed nutrients for growth.

This balanced approach helps broilers perform well and stay healthy. It’s especially important during the grower phase of production.

| Nutrient | Starter Feed | Grower Feed | Finisher Feed |

|---|---|---|---|

| Protein | 19-22% | 20-23% | 18-21% |

| Metabolizable Energy | 12.60 Mj/Kg | 13.00 Mj/Kg | 13.50 Mj/Kg |

| Calcium | 1.00% | 0.90% | 0.85% |

| Available Phosphorus | 0.50% | 0.45% | 0.40% |

The feeding schedule for broilers is designed to meet their changing needs. Adjusting protein, energy, and mineral levels in the feed helps. This ensures birds perform well and stay healthy.

Environmental Control in Poultry Sheds

Keeping the environment in poultry sheds just right is key to broiler chickens’ health and growth. As they get older, the focus moves from keeping them warm to cooling and ventilation. Temperature management is vital because broilers can get too hot and stressed.

Lighting programs help control when birds are active and when they rest. This helps them grow well and use their food efficiently. It’s important to watch and adjust the environment in the poultry house to keep the chickens comfortable and productive.

Temperature Management

The first day in a controlled house starts with a temperature of 32-34°C. The ideal humidity for poultry is 60-80%. The goal is to bring in air evenly and fast through vents above the birds.

Environment-controlled houses can raise about 7 flocks a year. This is more than the 4-5 flocks in open houses. They show better growth, feed use, and health.

Lighting Programs

Lighting is set at 0.5-1 fc and lasts 21-23 hours in the first two days for layers in ECH. ECHs are better because they keep temperatures even, grow birds faster, and use less labor.

“Careful examination of the grower contract is vital, including aspects such as payment terms, production requirements, incentive clauses, and potential scenarios.”

Broiler Health Monitoring

Keeping broiler chickens healthy is crucial during the grower phase. These birds are not as fragile as in the starter phase, but still face diseases. Growers work with vets and integrator field techs to keep them safe and healthy.

Watching the flock closely is essential for their growth. Growers check the birds often for signs of illness. They look for things like lethargy, less eating or drinking, breathing problems, or odd droppings. If they see anything wrong, they tell the vet team right away.

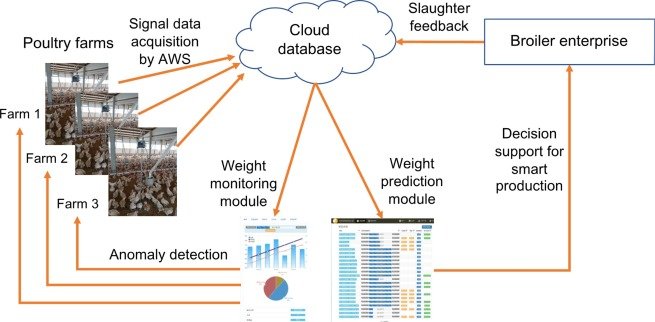

Growers also use tools like digital scales and growth software. These help them keep an eye on the flock’s health and performance. By being proactive, they can reduce disease impact and improve monitoring.

| Health Monitoring Activity | Frequency | Purpose |

|---|---|---|

| Visual Inspections | Multiple times per day | Identify signs of illness or distress |

| Weight Tracking | Weekly | Monitor growth and development |

| Feed and Water Consumption | Daily | Detect changes in appetite and hydration |

| Veterinary Inspections | Monthly | Comprehensive health assessment and treatment |

A detailed health monitoring plan helps keep broiler flocks healthy and productive. This sets them up for success in the final grow-out phase and a quality meat harvest.

Optimizing Feed Conversion Ratio

The feed conversion ratio (FCR) is key in broiler chicken production. It affects how much money you make. Feed Efficiency and Poultry Production Metrics depend on how well the birds eat and grow. Managing feed, feeding schedule, and water quality is crucial for a good FCR.

Keeping FCR low is vital for saving feed and making more money. A small drop in FCR can mean a big jump in profit. This shows how important it is to watch the birds and adjust care as needed.

The quality and nutrients in the feed matter a lot for FCR. Good feed leads to better eating and less waste. Tailoring feed to the birds’ needs and using smart feeding methods can improve the Broiler Feed Conversion Ratio.

Other things like animal health, genetics, and management also affect FCR. A strong biosecurity plan, the right environment, and using data can help. These steps can boost Feed Efficiency and Poultry Production Metrics.

By watching and improving Nutrition Management and Growth Optimization, growers can aim for the best Broiler Feed Conversion Ratio. This can help make their poultry business more profitable.

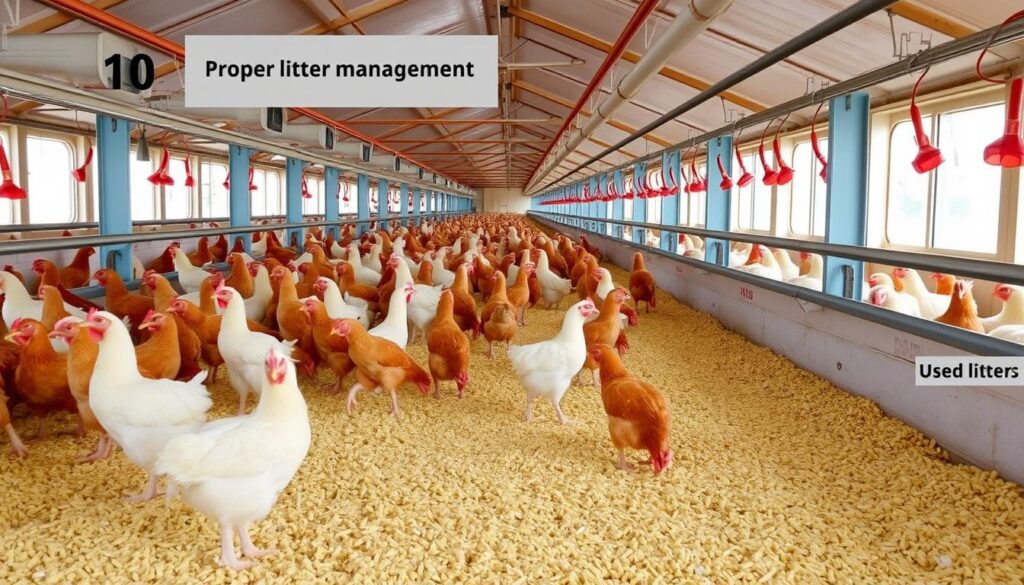

Litter Management for Broilers

Keeping the litter clean is key to broiler chickens’ health and growth. Growers need to check the litter’s moisture, Ammonia Control, and watch for diseases or pests. Good Litter Quality stops health issues like breathing problems and foot infections.

Broilers drink a lot of water, about two pounds for every pound of food. But, only 20% of this water helps them grow. The rest ends up in the litter as manure, causing problems like skin burns and blisters.

It’s important to keep the litter’s moisture between 20 tand25 percent. Using fans and ensuring good air flow helps manage moisture. This stops harmful bacteria from growing.

Controlling ammonia levels is also vital. Even small amounts can irritate the eyes and harm health. Growers must keep an eye on ammonia levels to protect their birds and workers.

The type of Bedding Materials used affects litter quality and ammonia. Pine shavings and sawdust are common, but can be hard to find and expensive. Growers must find reliable sources for these materials.

By following best practices in Broiler Chicken Litter Management, growers can ensure a healthy environment. This leads to better growth, health, and productivity on the farm.

The grower phase is key in Broiler Chicken Production. It requires careful management, feeding, and health checks. This ensures the birds grow well and reach their full potential.

Understanding the needs of the grower phase helps poultry farmers. They can improve their Poultry Farming Best Practices. This makes their operations more sustainable.

Feed quality and environmental conditions are vital in the grower phase. Keeping the right temperature, lighting, and feed quality boosts the birds’ growth. Also, watching the birds’ health closely and preventing diseases is crucial.

Using an Integrated Poultry Management approach is beneficial. It covers all aspects of the grower phase. This way, poultry farmers can make their Broiler Chicken Production sustainable and profitable.

This approach, combined with knowing the best practices, helps farmers. They can improve their flock’s growth and performance. This strengthens their poultry operations in the long run.