Creating the perfect broiler chicken house is key to boosting productivity and profits in poultry farming. It’s about setting up a space that helps birds grow well and keeps costs and labor low. A well-designed house can also improve bird health, efficiency, and care for the environment.

Broiler chicken housing is vital for poultry farming success. It doesn’t matter if it’s a big commercial farm or a small backyard setup. The design of the house greatly affects the birds’ health and productivity. By understanding their needs and using the right design, farmers can create a space that boosts their profits.

Introduction to Broiler Chicken Housing

Broiler chicken housing is key in modern poultry farming. It affects the health, welfare, and productivity of the birds. There are two main types: commercial (intensive) housing and backyard (free-range) housing.

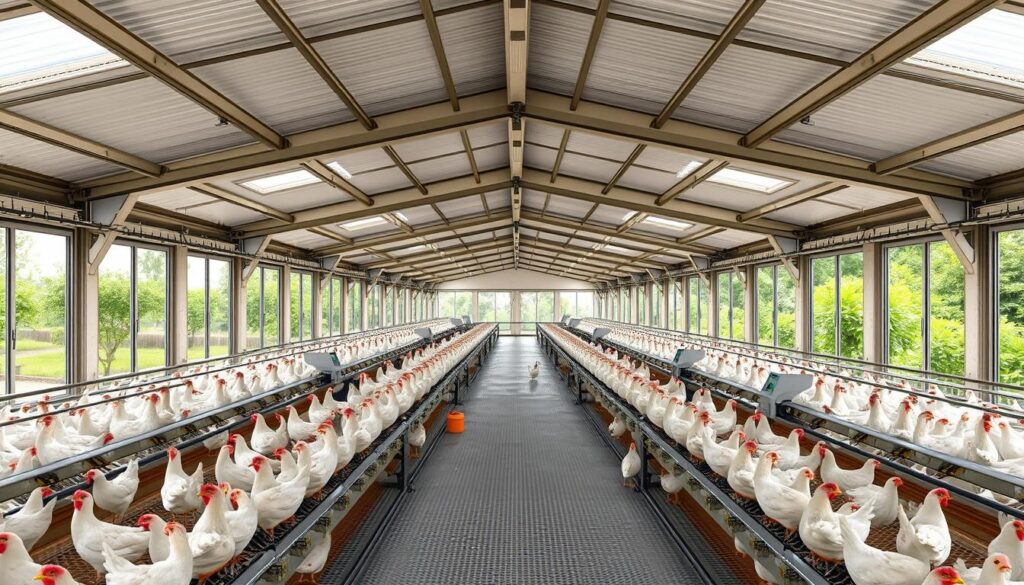

Commercial (Intensive) Housing

Commercial broiler houses are large and controlled. They can hold about 20,000 birds. These houses control temperature, humidity, and light to help the birds grow well. Commercial broiler housing is chosen for its biosecurity, better feed use, and high bird numbers.

Backyard (Free-Range) Housing

Backyard or free-range housing lets birds move outside. They get natural food and sunlight. This way of housing is healthier for the birds. But, it’s less efficient for big farms. Backyard broiler farming is good for small farms but faces challenges like disease and predators.

| Factors | Commercial (Intensive) Housing | Backyard (Free-Range) Housing |

|---|---|---|

| Stocking Density | High (20,000 birds per house) | Low (250 birds per hectare) |

| Environmental Control | Highly controlled (temperature, humidity, light) | Limited control (dependent on natural conditions) |

| Biosecurity | Enhanced (enclosed, controlled environment) | Lower (open access to outdoor environment) |

| Productivity | Higher (feed conversion, growth rate) | Lower (more labor-intensive, predator risks) |

| Animal Welfare | Potential for welfare concerns (lack of natural behaviors) | Improved welfare (natural environment, foraging) |

Choosing between commercial and backyard housing depends on the producer’s goals and resources. Both have advantages and disadvantages to think about when planning a broiler farm.

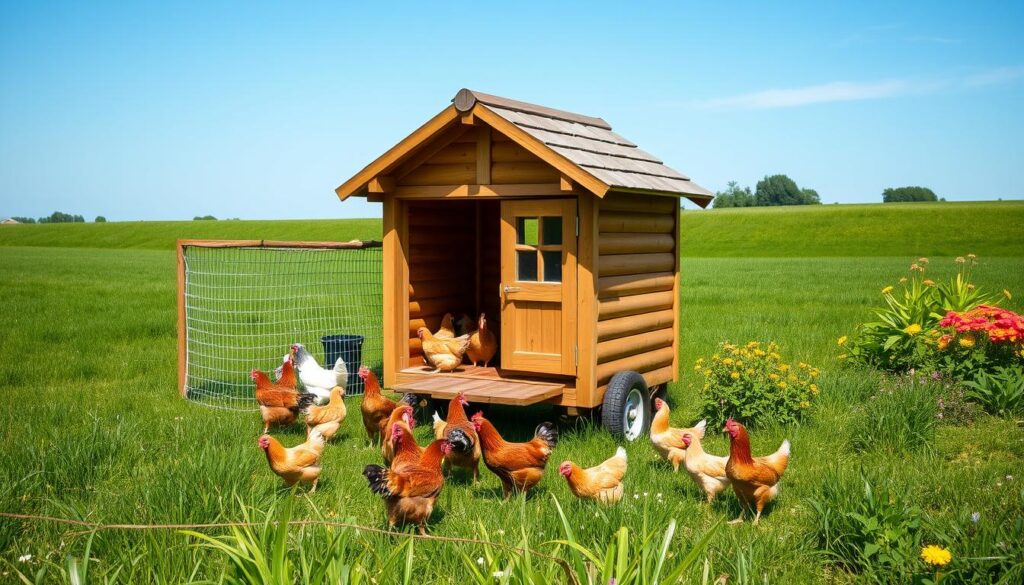

The Mobile Chicken House Solution

In the quest for efficient yet sustainable broiler farming, the concept of mobile chicken houses has emerged as a viable solution. This semi-intensive approach to Mobile Chicken Coops and Sustainable Broiler Farming combines the benefits of both commercial and free-range systems. It offers poultry farmers a middle ground that promotes bird health and farm profitability.

Mobile chicken houses are essentially portable, self-contained coops that can be moved across a farm. They allow the birds to forage on fresh ground while still providing the efficiency and automation of commercial housing. These mobile structures include features like automated feed lines, solar power, and advanced ventilation systems. They create an optimal environment for Semi-Intensive Broiler Housing that supports the natural behaviors of the birds while optimizing productivity.

Farmers who have adopted mobile chicken houses have reported remarkable results. According to our research, egg production rates have been boosted to around 80% by regularly moving the chickens in these mobile coops. Furthermore, 90% of egg businesses using mobile chicken houses have reported a growth rate after transitioning to these more efficient units.

“The mobility of these chicken houses has been a game-changer for our farm. We’ve seen a significant increase in productivity, and the birds are healthier and happier than ever before.”

The success of mobile chicken houses lies in their ability to provide a comfortable and stimulating environment for the birds. They also address the limitations of both commercial and backyard broiler housing systems. By striking a balance between efficiency and natural living, these innovative solutions are paving the way for a more Sustainable Broiler Farming industry.

Benefits of Mobile Chicken Coops

Mobile chicken coops bring many benefits to broiler production and sustainable farming. They allow birds to move to new grazing spots. This lets them forage naturally and eat a more nutritious diet.

This approach can improve the health and happiness of the birds. It also helps them grow better and feel more well-rounded.

Fresh Foraging Ground for Birds

The coops’ mobility means chickens always have access to fresh foraging ground. They can eat insects, seeds, and green grass. This diet meets their natural needs and gives them important nutrients.

This is a key advantage of raising broilers on pasture.

Healthy Soil and Grass

Mobile chicken coops also help the soil and grass. By moving the coop, manure is spread out evenly. This prevents the soil from getting too hard or lacking nutrients.

This keeps the soil healthy and encourages lush grass to grow. It supports sustainable poultry farming practices and the benefits of mobile chicken coops.

| Feature | Benefit |

|---|---|

| Fresh Foraging Ground | Improved Broiler Health and Welfare |

| Manure Distribution | Healthy Soil and Grass |

| Mobility | Sustainable Poultry Farming Practices |

“The ROVA|BARN400 helped Ferme JANAM in Quebec achieve autonomy on their farm, balancing farming with full-time careers through self-sufficient design.”

Optimal Broiler House Design Features

Designing a broiler chicken house requires careful planning. Key features are crucial for productivity and efficiency. One important aspect is the design of the access doors. Wide doors, at least four feet in size, are essential. They allow for easy movement of feed, equipment, and sick or injured birds.

This makes management easier and reduces stress for both the birds and the farmer.

Importance of Access Doors

The Broiler House Design Features should focus on wide access doors. Here’s why:

- They make it easy to move feed, equipment, and birds in and out.

- They reduce stress on the birds and the farmer during handling and management tasks.

- They improve the overall Efficient Poultry House Layout by making access easier for various operations.

By adding these wide access doors, broiler house managers can make their daily tasks easier. This boosts the Importance of Access Doors and helps the facility run better.

| Feature | Benefit |

|---|---|

| Wide Access Doors (Minimum 4 feet) | Ease of movement for feed, equipment, and birds; Reduced stress on birds and farmers |

| Efficient Poultry House Layout | Streamlined daily operations; Improved overall productivity |

How to Design the Perfect Broiler Chicken House for Maximum Productivity

Creating the perfect broiler chicken house needs a detailed plan. It involves looking at many factors in broiler house design. This way, farmers can make a space that helps their chickens grow well and be productive.

It’s important to think about how much space each bird needs. The recommended space per bird in a broiler chicken house is about 0.75 square feet. For 10,000 birds, you’ll need around 7,500 square feet of space.

Good ventilation and temperature control systems are key for maximizing broiler production. The optimal temperature range for broilers is between 70-75°F. They also need 16-18 hours of light each day.

Putting feeding and watering areas in the right spots can also boost productivity. Automated feed lines make things more efficient and save on labor. They ensure all birds get the food they need.

“By carefully planning the layout and incorporating the right design features, poultry farmers can create an environment that promotes the health, growth, and overall productivity of their broiler flocks.”

Designing the broiler house also means using the latest technology. Real-time monitoring systems and environmental sensors help keep everything running smoothly. They give farmers quick updates on conditions.

By focusing on these factors in broiler house design, farmers can make their broiler houses more productive. This leads to better yields and profits from their operations.

Automated Feed Lines for Efficiency

Adding automated feed lines to a broiler chicken house boosts efficiency and saves time. These Automated Feeding Systems for Broilers make feeding automatic, cutting down on manual work. They load feed into a big hopper and then give the right amount to each bird’s feeder. This saves labor and ensures each bird gets the right food, helping them grow evenly and reducing Efficient Broiler Nutrition Management.

The perks of Advantages of Automated Feed Lines go beyond saving time. They also make broiler operations more productive and profitable. By giving feed accurately and consistently, these systems help improve feed conversion rates. This leads to better cost control for poultry farmers.

| Automated Feeding Systems | Advantages |

|---|---|

| Lumina 40 Silo Weighing | Precise feed dispensing of up to 9,000 kg per hour |

| Lumina 41/42 Batch Weighing | Tailored feeding strategies for different poultry types |

| Lumina 44 BreederBatch | Reduced labor costs and enhanced feeding effectiveness |

Using precision farming techniques has also boosted the poultry industry’s productivity and sustainability. These advanced chicken feeder systems cut down on labor costs and make feeding more effective for farmers.

“Automating the feeding process can improve the feed conversion rate of animals, leading to better cost control for poultry farmers.”

Space Requirements for Broilers

It’s key to give broilers the right Broiler Stocking Density and Space Allocation for Broiler Chickens. This is for their health, happiness, and how well they do their job. The National Chicken Council says each bird should have about 0.8 square feet. But some say up to 1.3-2.4 square feet is better to stop overcrowding and let them move freely.

Keeping the coop well-insulated helps chickens stay cool in hot weather. The bedding should be 10 cm deep for comfort. Also, using smooth materials in the coop helps prevent injuries and makes cleaning easier.

| Broiler Housing Specification | Minimum Requirement | Recommended Optimal |

|---|---|---|

| Space Allocation per Bird | 0.5 square feet | 1.3-2.4 square feet |

| Bedding Depth | 10 cm | 10 cm |

| Maximum Stocking Density | 0.8 square feet per bird | 1.3-2.4 square feet per bird |

By giving broilers the right Broiler Stocking Density and Space Allocation for Broiler Chickens, producers can make sure they’re happy and healthy. This leads to a more productive flock.

H Type Broiler Cage Systems

The H type broiler cage is a modern housing solution. It optimizes space and improves broiler chicken management. These stacked cages let more birds live in a smaller area. This makes broiler production more efficient.

Advantages of H Type Broiler Cages

- Improved space efficiency, enabling higher stocking densities

- Enhanced management capabilities through automated systems

- Better hygiene and sanitation with integrated manure removal

- Potential cost savings through more efficient use of resources

Features to Look for in Broiler Cage Systems

When choosing broiler chicken cage systems, consider these key points:

- Durability of the materials, ensuring long-term performance

- Ease of maintenance and cleaning for optimal hygiene

- Adequate ventilation to maintain ideal environmental conditions

- Incorporation of automated systems for feeding, watering, and waste removal

By evaluating these features, you can find the best broiler cage system. It should balance productivity, efficiency, and animal welfare for your farm.

| Specification | H Type Broiler Cage |

|---|---|

| Tiers | 3-12 tiers |

| Cage Capacity | 20, 23, or 32 birds per cage |

| Feeding System | Single-side feeding |

| Service Life | Up to 30 years |

“The H-type broiler cage system offers different variations in tiers, accommodating 20, 23, or 32 birds per cage.”

Implementation and Best Practices

To make a broiler chicken house work well, you need a solid plan. This includes picking the right spot, designing a smart layout, and using top-notch materials. It’s also important to follow the maker’s instructions for any special gear, like cage systems.

After setting up the house, keeping it clean and watching the birds’ health is key. You should also tweak the environment often. Following Implementing Broiler Chicken Houses, Best Practices in Broiler Farming, and Successful Broiler House Management helps a lot. This way, you can make your poultry business more efficient and profitable.

Sticking to the best practices and using new tech, like IoT systems, can really help. It boosts productivity, makes the environment better, and increases your earnings. This approach helps poultry farmers in the U.S. stay ahead in the fast-changing broiler market.