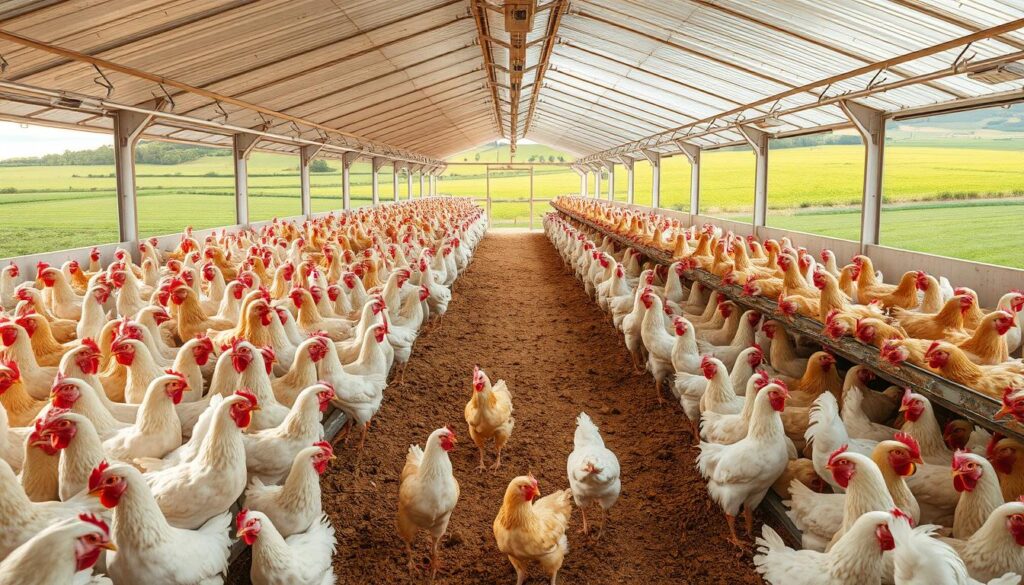

The global broiler industry has made big steps in creating efficient and sustainable housing. These systems are key to meeting the world’s growing demand for chicken meat. By using the best practices in broiler chicken housing, producers can improve their operations’ performance, welfare, and profits.

Enclosed housing models are now the norm in the industry. They provide a controlled space that keeps broilers safe from diseases carried by wild animals and birds. These houses have important functions like heating for brooding, ventilation for air, and protection from predators and pests.

The most common sizes for broiler houses are between 30′ to 66′ wide and 300′ to 600′ long. Steel truss houses are more efficient and have fewer rodent problems than wood truss houses.

Proper stocking density is vital for broiler performance, uniformity, and welfare. By managing the number of birds per square meter, producers can balance productivity with animal well-being.

Case Studies: Successful Broiler Chicken Housing Models Around the World

Broiler housing models vary globally. Europe focuses on sustainable practices and animal welfare. North America uses advanced technologies for broiler production. These examples show innovative designs and efficient solutions for poultry farming.

Sustainable Practices from Europe

A study in Brazil looked at housing effects on broiler flocks. It involved over 100 million birds from 977 farms. The study found that certain housing features reduced mortality and improved feed conversion ratio.

Advanced Technologies in North America

In North America, producers use advanced technologies. A study in a state collected data from 3,516 commercial chicken flocks over a year. It found that specific housing features impact production, welfare, and meat quality.

| Housing Feature | Impact on Mortality | Impact on Feed Conversion Ratio (FCR) |

|---|---|---|

| Positive Ventilation | Reduced Mortality | Improved FCR |

| Metal and Clay Roof | Reduced Mortality | No Significant Impact |

| Dirt Floor | Reduced Mortality | No Significant Impact |

| Concrete Floor | No Significant Impact | Improved FCR |

| Negative Ventilation | No Significant Impact | Improved FCR |

| Blue Curtains | No Significant Impact | Improved FCR |

| Fluorescent Lighting | No Significant Impact | Improved FCR |

| Owner Management | Reduced Mortality | Improved FCR |

| Tap Water | No Significant Impact | Improved FCR |

| Well Water | No Significant Impact | Improved FCR |

These studies show the value of innovative housing models and sustainable practices. They are key to efficient and welfare-focused broiler production worldwide.

Enclosed Housing: The Industry Standard

Enclosed broiler chicken housing is the top choice for modern poultry farming. These controlled spaces protect broilers from diseases and pests. They have a solid base to keep out unwanted animals.

Insulation is key in these houses. It keeps the flock warm in winter and cool in summer. Ventilation systems also play a big role. They bring in fresh air and remove bad gases and moisture.

Optimal Broiler House Dimensions and Materials

Broiler houses are usually 43 feet wide and 500 feet long. This size allows for efficient farming. They are built with metal, wood, or a mix of both.

Steel truss houses are more efficient and have fewer rodent problems. They also build faster. Wood truss houses are cheaper but can be made to work well with tunnel ventilation and heating.

| Housing Type | Advantages | Disadvantages |

|---|---|---|

| Steel Truss |

|

|

| Wood Truss |

|

|

“Enclosed housing systems enable broiler producers to protect their flocks and ensure their overall health and wellbeing.”

Stocking Density: Balancing Welfare and Productivity

Finding the right balance between broiler stocking density, animal welfare, and production is key. The number of birds per floor space depends on climate, season, and housing type. It also depends on the target weight and local laws.

Recent studies have shown how growth rate and stocking density affect broiler welfare. Slower-growing birds have better feathers, walking, and bone health than fast-growing ones. But, they eat more feed and take longer to grow.

| Growth Rate | Days to 3 kg | Feed Conversion Ratio | Feather Coverage | Gait Score |

|---|---|---|---|---|

| Standard | 45 | 1.57 | Poorer | Poorer |

| Medium | 52 | 1.67 | Moderate | Moderate |

| Slower | 62 | 1.80 | Better | Better |

New technologies like RFID and image processing help measure broiler welfare. They look at activity, feather condition, and lameness. This data helps decide the best stocking density for both efficiency and animal care.

The demand for chicken meat is growing, and the industry must adapt. By managing stocking density and using new tech, producers can make the broiler industry more sustainable and ethical.

“Selecting strains with better welfare outcomes for commercial production has been a challenge, with limited success in reducing welfare problems.”

Efficient Feeder Systems for Broiler Chickens

Broiler chickens need enough space to eat well. This is key for them to grow fast and evenly. Automatic round pan feeders are the norm, measuring 12 inches in diameter. They can feed up to 4,580 birds, adjusting for bigger birds.

These feeders use a metal tube and an auger system to spread out the feed. This setup has many benefits. It fills faster, lets birds move freely, cuts down on waste, and adjusts to the birds’ growth. Feed bins outside hold 10-12 tons, keeping the supply steady.

Automatic Round Pan Feeders

Automatic round pan feeders are a top pick for broiler houses. They beat old ways of feeding in many ways. They’re part of a system that moves feed from bins to the pans in the house.

- Faster fill times: The auger system quickly fills the pans, keeping feed flowing.

- Unrestricted bird movement: The pans’ design lets birds move freely while eating.

- Reduced feed wastage: The feeders’ design and the birds’ eating habits cut down on waste.

- Easy height adjustment: The feeders adjust to the birds’ size, making sure they can always reach the feed.

Feed Storage and Distribution

Good feed management is vital for broiler operations. It includes storing and distributing feed well in the chicken house. Each house has two 10-12 ton bins, placed in the middle or at one end.

| Metric | Value |

|---|---|

| Feed Storage Capacity | 5 days of feed consumption |

| Feed Bin Watertightness | Necessary to reduce mold and bacterial growth |

| Dual Feed Bin System | Allows for rapid feed changes and prevents mixing of old and new feed |

Having enough feed storage and keeping bins watertight is crucial. It keeps the feed fresh and prevents contamination. The dual bin system also makes it easy to switch feed types without mixing them.

Closed Water Systems: A Game-Changer

The broiler industry has seen big changes since closed water systems were introduced in the early 1990s. These systems are cleaner than open ones. They also help keep the litter dry, which is better for the birds’ health. Low-flow rate nipple drinkers and high-flow rate ones with cups are the main types used.

Low-Flow and High-Flow Nipple Drinkers

Low-flow nipple drinkers give water at up to 2 fluid ounces per minute. They can serve about 10 chickens per nipple. On the other hand, high-flow ones with cups can serve around 12 chickens per nipple. These systems make water management in poultry farming more efficient and controlled. They ensure the best broiler closed water systems and water management in poultry farming.

| Drinker Type | Flow Rate | Chickens per Nipple |

|---|---|---|

| Low-Flow Nipple Drinkers | Up to 2 fluid ounces per minute | 10 chickens |

| High-Flow Nipple Drinkers with Cups | Higher than Low-Flow | 12 chickens |

Closed water systems are less likely to be contaminated than open systems, and better control of water usage by the birds keeps the litter drier, improving bird health.

Lighting Systems: Optimizing Broiler Performance

Lighting is key in broiler chicken production, making up 25-40% of electrical costs. The light’s intensity and how long it’s on, or photoperiod, affects the birds’ eating habits, health, and happiness. Experts suggest giving broilers 4 to 6 hours of darkness daily to boost feed efficiency and lower health problems in broiler chickens.

Before, broiler houses used old incandescent bulbs. Now, they’re switching to CFL and LED bulbs for better energy use. These broiler lighting systems cut down on energy use and let producers control light intensity and photoperiod for broilers better, helping the birds perform their best.

Studies show that different lights can change things like body weight, hatchability, and chick quality. The best light color and intensity for poultry, especially chickens, is still being studied. As energy-efficient lighting in poultry farming gets better, so does our understanding of it.

| Lighting Parameter | Recommended Range |

|---|---|

| Light Intensity | 5-10 lux during brooding, 10-20 lux during grow-out |

| Photoperiod | 20-23 hours of light per day during brooding, 16-18 hours of light per day during grow-out |

| Light Color | Cool-white, blue, or green light preferred for optimal performance |

“Lighting is a vital component of broiler production, representing 25-40% of electrical costs. Light intensity and photoperiod directly influence the time broiler chickens spend eating, as well as their general health and well-being.”

Achieving Optimal Broiler Performance through Lighting

By managing broiler lighting systems well, producers can greatly improve their flock’s performance and health. Using energy-efficient lights, like LEDs, cuts costs and lets producers control the birds’ environment. This promotes better growth and feed efficiency.

Heating Systems: Essential for Brooding Success

Keeping the right temperature is key for broiler chickens’ health and growth, especially in the brooding stage. Heating systems in broiler houses are vital for brooding success and the whole production cycle.

There are two main heating methods: convection and radiant. Convection uses air heaters for even temperature across the house. Radiant heating, or infrared, warms chicks and their area directly.

Space heaters are placed in the house’s middle, where air moves slowly. This keeps chicks from seeking warmer spots. It ensures a steady, ideal environment for them during brooding.

“Proper brooding is essential for chick success and can have a lasting impact on the overall performance of the flock.”

Choosing the right heating system affects energy use and costs in broiler production. For example, a study compared green and traditional houses. The green houses used less energy, especially in cold seasons.

The poultry industry needs to move towards sustainable, energy-saving broiler house heating systems. This will boost brooding for chick success and make broiler operations more profitable. Using convection and radiant heating in poultry houses helps farmers save resources, reduce environmental harm, and keep their flocks healthy.

Ventilation: Maintaining Healthy Air Quality

Keeping the air clean in broiler houses is key. These houses have air inlets on the sides for fresh air. An exhaust fan pulls air out, bringing in oxygen and removing harmful gases and moisture.

Good air quality is vital for broiler house ventilation and air quality management in poultry. It helps birds stay healthy and productive. Studies show air quality affects broiler health and growth.

New tools like computational fluid dynamics (CFD) help manage air in broiler houses. These tools simulate airflow, temperature, and humidity. They help producers spot and fix air quality issues early.

| Key Factors for Maintaining Healthy Air Quality in Broiler Houses | Benefits |

|---|---|

|

|

By focusing on broiler house ventilation and air quality management, producers can improve their flocks’ health and performance. This leads to better success in their operations.

Global Case Studies: Innovative Broiler Housing Solutions

Broiler housing varies around the world, showing different ways to farm sustainably. In Europe, they focus on being productive while caring for animals and the environment. They use new housing that gives birds lots of space, light, and fresh air. This meets the need for farming that’s good for the planet.

Sustainable Practices from Europe

European broiler farms use many green practices. They focus on animal care and protecting the environment. Here are some of their methods:

- They create big, rich environments for birds to act naturally.

- They use natural light and air systems to save energy.

- They give birds places to go outside and explore.

- They have systems that reuse waste, cutting down on environmental harm.

Advanced Technologies in North America

In North America, farms use new tech to improve their work. They use the latest in housing to make farming better. Some of these include:

- They have systems that feed and water birds perfectly, cutting down on waste.

- They control the environment exactly for the birds’ health.

- They use data to make smart choices about resources and bird care.

By using these global best practices and new tech, farms everywhere are making a greener future. They meet the need for innovative broiler farming practices and sustainable poultry production.

| Region | Key Innovations in Broiler Housing | Sustainability Impact |

|---|---|---|

| Europe |

|

|

| North America |

|

|

Poultry Welfare Considerations in Broiler Housing

Ensuring the welfare of broiler chickens is vital in broiler housing design and management. It’s important to provide enough space, keep temperatures and air quality right, and meet the birds’ natural needs. Balancing profit with ethics and sustainability is a big goal for producers globally.

Studies from the 1970s show caged broilers perform better than those on the floor. Yet, cages can harm their behavior and cause issues like breast blisters. The height of pens, how many birds are in them, and living conditions affect their bones and meat quality.

Stocking density greatly affects broiler welfare and behavior. Too many birds can cause serious health problems, like skeletal issues and ascites. It’s crucial to give broilers enough room to stay healthy.

New ideas, like analgesic drug self-selection for lame broilers, aim to improve welfare. The industry faces growing pressure to improve animal care and the environment. Finding a balance between profit, animal welfare, and sustainability is a big challenge.

“The multi-state project involves collaborators from various fields such as nutritionists, environmental physiologists, neuroscientists, behaviorists, engineers, operations researchers, extension specialists, and economists.”

The International Poultry Welfare Alliance (IPWA) has a detailed Key Welfare Indicators (KWIs) guide. This guide, made by a group of experts, helps improve poultry welfare globally.

The poultry industry must tackle animal welfare while keeping production and profit up. New housing ideas, research partnerships, and efforts like the IPWA’s KWIs guide are key to a better future for broiler farming.

Best Practices for Efficient Broiler Housing Management

To get the best results and make a profit in broiler production, you need good management in the housing. This means keeping the right number of birds, making sure they eat and drink well, and keeping the place clean and safe. It also means taking care of the environment and the birds’ well-being.

Using these smart strategies can help broiler farms work better and last longer. A study looked at 31 farms and found only two were close to being the most efficient. This shows how important it is to look at costs and how to make them better.

It’s also key to keep checking and improving how well the birds are treated. This includes things like air quality, how many birds die, how clean the litter is, and the health of their feet. The International Poultry Welfare Alliance has made a detailed guide for checking these important areas. Over 90 groups and 30 scientists helped make it.