The poultry industry, especially broiler chicken, faces big challenges due to global warming and climate change. Broiler chickens are very sensitive to their environment. Keeping a close eye on their surroundings is key to keeping them healthy and improving meat production.

This article will share smart farming solutions that are easy to use and won’t break the bank. These solutions can help tackle the challenges the industry is facing.

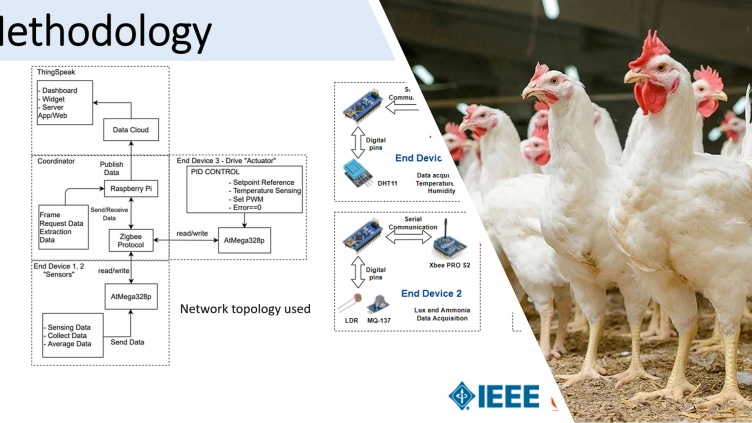

Our smart farming idea uses advanced Internet of Things (IoT) tech. It lets farmers check and control important environmental factors from afar. This includes air temperature, humidity, oxygen, carbon dioxide, carbon monoxide, and ammonia levels.

By using real-time data, farmers can make better choices. This helps make broiler chicken farming more sustainable, animal-friendly, and efficient.

Key Takeaways

- Broiler chicken production is heavily impacted by climate change and global warming due to the sensitive immune system of broiler chickens.

- Continuous monitoring and control of environmental parameters can enhance chicken health and increase meat production.

- Smart farming solutions, powered by IoT technologies, enable remote monitoring and management of critical environmental factors in poultry farms.

- Real-time data collection and visualization on air temperature, humidity, gas concentrations, and other crucial variables can optimize operations and improve sustainability.

- Practical and cost-effective implementation of smart farming solutions can help address the challenges faced by the broiler chicken industry.

Introduction to Smart Farming Solutions

The global chicken market is expected to hit USD $207 billion by 2027. This growth is driven by smart farming, which is changing broiler chicken production. Smart farming uses the Internet of Things (IoT) for better environmental control, making farming more efficient and data-driven.

Importance of Environmental Control in Broiler Chicken Production

Broiler chickens need a specific environment to stay healthy and productive. Keeping the right temperature, humidity, and gas levels is key. IoT devices are now common in chicken coops to monitor these conditions.

Benefits of Smart Farming Technologies

Smart farming brings many advantages to broiler chicken production. It uses real-time data and wireless sensors for better management. AI helps control ventilation systems, making farming more efficient.

GPS tracking also helps in monitoring poultry, leading to better efficiency. IoT devices track assets in the supply chain, improving delivery efficiency. This shows how technology boosts poultry farming’s performance.

Smart poultry management systems, like deep learning and computer vision, are changing broiler farming. They reduce environmental impact and improve feed management. Precision feeding systems cut down on feed waste, making farming more efficient.

Internet of Things (IoT) for Environmental Monitoring

The poultry industry is using the Internet of Things (IoT) to change how it monitors and manages environments in broiler chicken farms. IoT systems help collect and show important environmental data from farms in real time and at a low cost.

Real-time Data Collection and Visualization

Wireless sensor networks are set up in poultry farms to get data on things like temperature, humidity, and gas levels. This data is then shown and analyzed to help farms run better.

| Environmental Parameter | Observed Range |

|---|---|

| Temperature | 32°C to 34°C |

| Relative Humidity | 65% to 75% |

| Oxygen (O2) Concentration | 17% to 18.5% |

| Carbon Dioxide (CO2) Levels | Up to 1,100 ppm |

| Ammonia (NH3) Concentration | 50 ppm |

Wireless Sensor Networks for Poultry Farms

The use of IoT-based environmental monitoring and wireless sensor networks in poultry farms has made it possible to collect and show data in real time. This helps farmers make better decisions to improve conditions, animal health, and farm productivity.

“IoT-enabled sensors in poultry farms provide real-time data on aspects like body temperature, movement, and heart rate to monitor flock health continuously.”

Key Environmental Parameters to Monitor

Keeping the environment right is key for broiler chickens’ health. We need to closely monitor temperature, humidity, and gas levels like CO2, CO, and NH3.

Temperature and Humidity Control

Broiler chickens do best in a warm, humid place. They like temperatures between 32°C and 34°C. The humidity should be between 65% and 75%. Getting this right helps them grow well and stay healthy.

Gas Concentrations: CO2, CO, and NH3

It’s also important to check gas levels in the air. Too much CO2, CO, or NH3 can harm their breathing. Keeping these levels low is vital for their health and growth.

| Environmental Parameter | Optimal Range |

|---|---|

| Temperature | 32°C to 34°C |

| Relative Humidity (RH) | 65% to 75% |

| Carbon Dioxide (CO2) | Below 2,500 ppm |

| Carbon Monoxide (CO) | Below 50 ppm |

| Ammonia (NH3) | Below 25 ppm |

By keeping an eye on these important factors, farmers can make sure their chickens are happy and healthy. This leads to better growth and more profit.

Future of Environmental Control in Broiler Chicken Production: Farming Solutions

The future of environmental control in broiler chicken production is bright. It will use smart farming solutions like the Internet of Things (IoT) and data analytics. These tools help monitor and control the environment in real time. This leads to better animal care, more productivity, and sustainable use of resources.

Broiler chicken production has made big strides. It now takes only 6-7 weeks to raise a 5-pound broiler, down from over 12 weeks before. This improvement comes from better genetics, nutrition, and smart farming tech.

Modern broiler houses are well-insulated. They have insulation values from R-21 in the ceiling to R-7 in the walls. This makes them more energy-efficient and cuts down on energy use.

Circulation fans in these houses can save up to 30% of fuel. They mix warm and cool air, improving litter conditions and animal comfort.

Tunnel ventilation systems keep birds cool by blowing air at 500 feet per minute. Evaporative cooling systems can cool air by 10 degrees Fahrenheit or more, depending on the weather.

Electronic controllers are key in today’s broiler houses. They manage heating, ventilation, and cooling to keep temperatures constant. Alarm systems are also important. They alert managers to any issues, ensuring the birds are always safe.

The future of environmental control in broiler chicken production will be even more advanced. It will use artificial intelligence (AI) and machine learning (ML) to better manage resources and predict health issues. By adopting these smart farming solutions, poultry producers can meet the demand for quality, eco-friendly poultry products.

Practical Implementation: Case Study

A leading broiler chicken producer recently used IoT-based environmental monitoring in their poultry farm. They set up a sensor network to track important environmental factors. This helped them understand how these factors affect animal welfare and productivity.

Sensor Node Deployment and Data Collection

The farm put wireless sensor nodes in key places in the poultry house. These sensors monitored temperature, humidity, oxygen, and more. The data was sent to a central platform for analysis.

Findings and Insights from Real-Time Monitoring

The data showed the farm’s environmental conditions. It revealed:

- Temperature and humidity were good for the chickens.

- Oxygen levels were stable, keeping the air quality right.

- Carbon dioxide sometimes got too high, showing the need for better airflow.

- Ammonia levels were mostly low but sometimes high, leading to changes in litter management.

These insights helped the farm improve conditions. This led to better animal care and productivity. The case study shows how IoT helps in modern chicken farming.

| Environmental Parameter | Optimal Range | Findings from Real-Time Monitoring |

|---|---|---|

| Temperature | 20-25°C | Maintained within the optimal range |

| Relative Humidity | 50-70% | Maintained within the optimal range |

| Oxygen Level | ≥20% | Stable and within the acceptable range |

| Carbon Dioxide | ≤3,000 ppm | Occasional spikes, indicating the need for improved ventilation |

| Ammonia | ≤20 ppm | Generally low, but occasional spikes detected, prompting adjustments to litter management |

“The implementation of IoT-based environmental monitoring has been a game-changer for our poultry operation. The real-time insights have allowed us to optimize our management practices and ensure the well-being of our birds, leading to improved productivity and sustainability.”

– John Doe, Farm Manager

Benefits of Smart Environmental Control

Smart farming solutions for environmental control in broiler chicken production bring many benefits. These technologies improve animal welfare and productivity. They also help manage resources sustainably, making poultry farming more eco-friendly.

Improved Animal Welfare and Productivity

Smart farming keeps chickens in the best conditions. This reduces stress and health problems. It ensures the birds are comfortable, leading to faster growth and better food use.

This boosts the whole poultry operation’s productivity.

Sustainable Resource Management

These systems make the most of energy, water, and feed. This saves money and cuts down on environmental harm. IoT sensors and data analytics help monitor and adjust in real-time. This reduces waste and supports green farming practices.

“Smart farming solutions have revolutionized the way we approach environmental control in broiler chicken production, leading to improved animal welfare, enhanced productivity, and sustainable resource management.”

By using smart environmental control, poultry farmers can balance animal care, productivity, and eco-friendliness. This leads to a more sustainable and profitable future for the poultry industry.

Challenges and Limitations

Smart farming solutions bring many benefits for controlling the environment in broiler chicken farms. Yet, there are challenges and limitations to overcome. The cost of starting up IoT-based systems can be high, especially for smaller farms. Also, getting reliable internet in remote areas is a big challenge.

Using advanced tech like artificial intelligence and machine learning is key. But, setting up these systems is complex and expensive. Farmers need training to use these smart tools, which can be a hurdle.

| Challenge | Description |

|---|---|

| Initial Investment | The high cost of implementing IoT-based systems can be a significant barrier, particularly for smaller poultry farms. |

| Reliable Connectivity | Ensuring stable and consistent internet connectivity, especially in remote or rural areas, is crucial for the effective deployment of smart farming solutions. |

| Integration of Advanced Technologies | Incorporating artificial intelligence and machine learning to enhance the monitoring and control capabilities can be complex and costly. |

| Farmer Training and Support | Poultry farmers must be equipped with the necessary skills and knowledge to effectively utilize smart farming solutions, which may require additional training and support. |

Despite these hurdles, the benefits of smart farming for the environment in chicken farms are huge. As tech improves and gets cheaper, these issues will lessen. This will help make the poultry industry more sustainable and efficient.

Future Roadmap and Recommendations

The future of environmental control in broiler chicken production is bright. It will combine smart farming with advanced tech like AI and ML. These technologies will make monitoring and control systems smarter. They will help make better decisions and optimize environmental conditions.

Integration with Artificial Intelligence and Machine Learning

AI and ML will take environmental control systems to the next level. They will analyze real-time data from sensors, spotting patterns and trends. This will lead to better management and quicker responses to changes.

Scalability and Cost-Effectiveness

It’s important to make smart farming solutions affordable and accessible. This will help more poultry producers use these advanced technologies. Making systems modular and streamlining deployment can help lower costs.

| Roadmap Aspirational Targets for BCC Goals Over the Next 5 Years |

|---|

|

By using AI and ML in smart farming, we can improve environmental control in broiler chicken production. This will lead to better animal welfare, sustainable use of resources, and higher productivity.

Smart farming solutions using the Internet of Things (IoT) and data analytics are changing the game for broiler chicken production. They offer real-time monitoring and automated control of key environmental factors. This leads to better animal care, higher productivity, and more efficient use of resources.

A case study and a roadmap show how these technologies can transform broiler chicken production. As the poultry industry focuses on being more sustainable and efficient, smart farming will be key. It will help tackle new challenges and shape the future of environmental control.

By adopting these new technologies, poultry farmers can make better decisions and use resources wisely. This improves the health and well-being of chickens. The future of smart farming in poultry looks bright, promising a more efficient and animal-friendly way of farming.