Broiler chickens are bred for their fast growth and efficient meat production. The demand for affordable poultry meat has made the broiler industry grow. To meet this demand, breeders focus on increasing the breast muscle size. This allows broilers to reach slaughter weight faster than other chicken breeds.

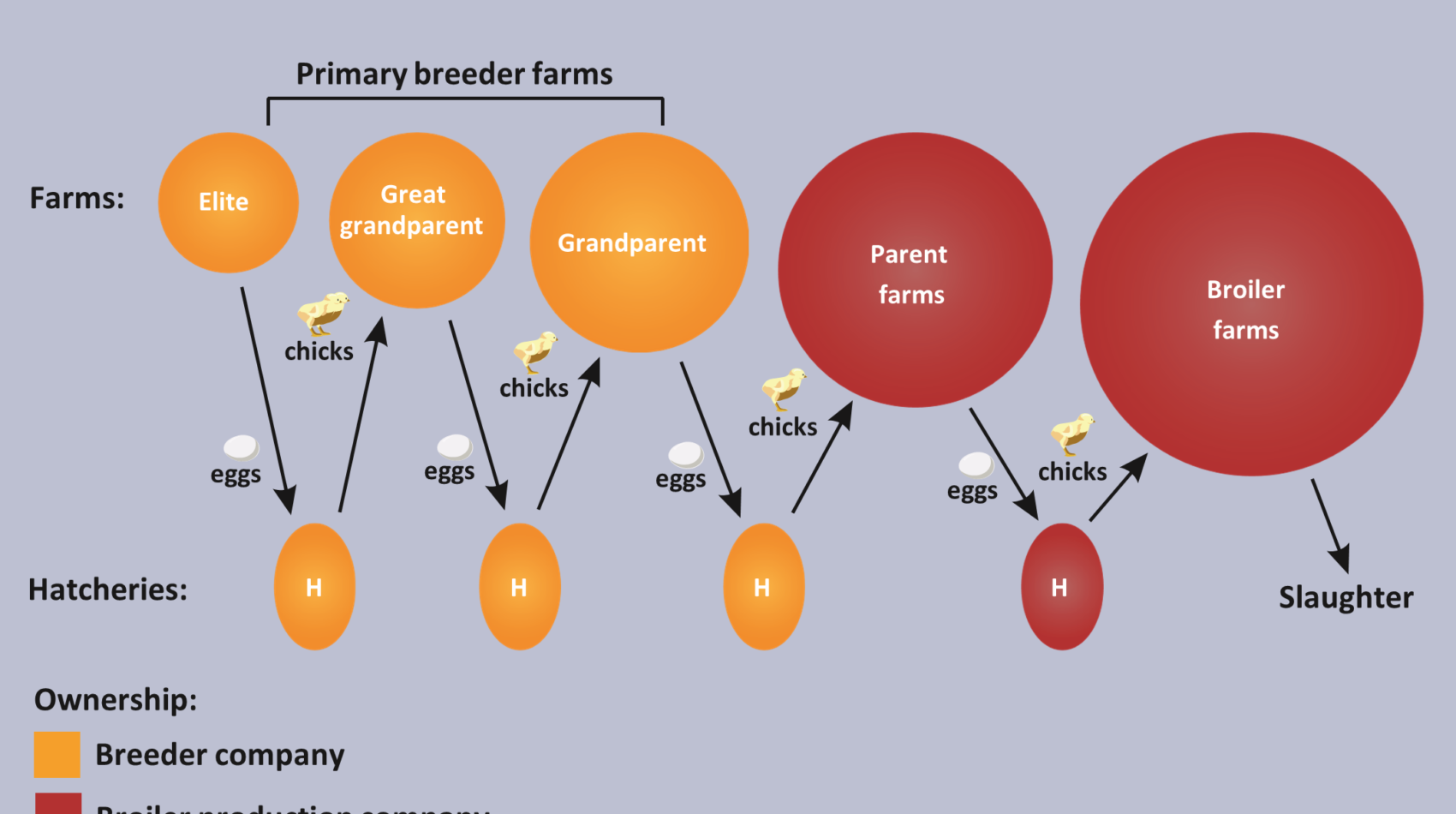

The broiler chicken lifecycle has two main phases. First, they hatch in a hatchery. Then, they grow on a farm until they reach the desired weight for slaughter.

Key Takeaways

- Broiler chickens are bred for rapid growth and efficient feed conversion to meet consumer demand for affordable poultry meat.

- The broiler chicken lifecycle involves hatching in a hatchery and growing out on a farm until reaching the desired slaughter weight.

- Breeding and nutrition advancements have enabled broiler chickens to reach market weight faster compared to traditional meat chicken breeds.

- Broiler chickens are often raised in large flocks under intensive indoor farming systems, with practices like thinning used to manage growth.

- Broiler processing and slaughtering are important final steps in the broiler chicken lifecycle before the meat reaches consumers.

Introduction to Broiler Chicken Production

What are Broiler Chickens?

Broiler chickens, or meat chickens, are raised for their meat. They come from the jungle fowl of the Indian Subcontinent. These birds grow fast and convert feed into meat efficiently.

Unlike laying hens, broilers live for only a short time. They are usually slaughtered at 5-6 weeks old.

The History and Growth of the Broiler Industry

The broiler industry has grown a lot in recent decades. This growth is due to more people wanting affordable chicken meat. Better breeding, nutrition, and production methods have helped.

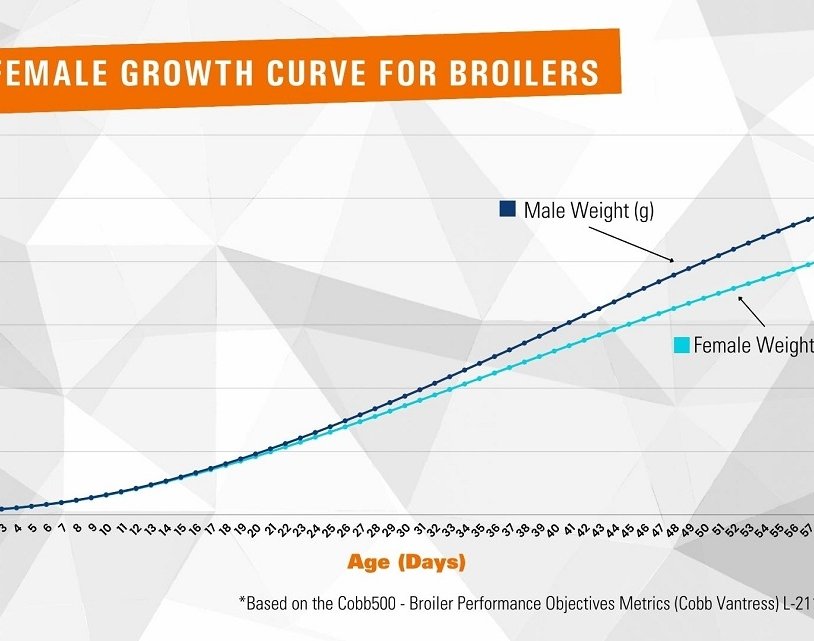

In the past 80 years, the slaughter age of a standard fast-growing broiler has decreased considerably, while the final market weight has significantly increased. This change has made chicken meat more popular and accessible worldwide.

“Chick meat accounts for the highest consumption of meat globally and continues to see increasing demand.”

The industry’s growth is also because chicken meat is affordable and versatile. It’s good for healthy diets and is popular in developing countries. So, chicken meat consumption is rising faster than other meats globally.

The Broiler Chicken Lifecycle: From Hatch to Market-Ready

The broiler chicken lifecycle is a well-planned journey. It starts at the hatchery and ends when the chicken is ready for market. This process shows how the poultry industry meets the world’s growing need for chicken.

It all begins with “day-old chicks.” These chicks are moved from the hatchery to broiler farms. There, they grow in controlled environments until they’re ready to be slaughtered, usually in 5-7 weeks.

Modern broiler farms use advanced methods to help chickens grow well. Most commercial broilers are ready to be slaughtered in 4-6 weeks. But slower-growing breeds might take up to 14 weeks. The way they convert feed into meat has also gotten better. The U.S. average is now 1.91, and New Zealand leads the world at 1.38.

The broiler chicken lifecycle shows the poultry industry’s ongoing progress. From the hatchery to the farm, this journey ensures a steady supply of chicken. As the industry keeps improving, the broiler chicken lifecycle will be key in shaping the future of food.

The Hatchery and Chick Handling

The broiler production starts at the hatchery. Here, eggs from breeder birds incubate under perfect conditions. After 21 days, chicks hatch, using their egg tooth to break free.

Newly hatched chicks are called “day-old chicks.” They are up to 72 hours old when they leave the hatchery.

Incubation and Hatching Process

The incubation and hatching process is key in the broiler chicken life cycle. It takes about 21 days for a chick to grow inside its egg. After hatching, chicks stay in an incubator for a day.

Then, they move to a brooder. Here, the temperature lowers as they grow their true feathers.

Vaccination and Transportation of Chicks

Before leaving the hatchery, broiler chicks get vaccinated. They are protected against diseases like Newcastle disease and coccidiosis. Vaccines are given through spraying, drinking water, or injection.

Chicks are then transported to the broiler farm in special modules. These modules keep the chicks comfortable. They can’t control their body temperature yet and are prone to stress.

| Key Statistics | Value |

|---|---|

| Incubation period | Approximately 21 days |

| Newly-hatched chick weight | Around 44g |

| Broiler chick value | $0.36 per chick |

| Broiler feed consumption | Approximately 9 pounds |

| Broiler market weight | 5 pounds in 5 weeks |

“The modern broiler can achieve a 5-pound market weight in five weeks, whereas it took 10 weeks to achieve a 4-pound market weight forty years ago.”

Broiler Housing and Management

More than 70% of broiler chickens worldwide live in intensive (industrial) farming systems. These systems have large, climate-controlled sheds. They have automated feeding and watering for the birds. Each shed can hold 10,000 to 20,000 birds or more.

Broilers in these systems grow fast and are ready for slaughter at 5-7 weeks.

Intensive (Industrial) Farming Systems

Intensive farming systems control the environment for broiler chickens. This helps them grow fast and efficiently. The systems manage temperature, ventilation, and lighting well.

This setup allows for large meat production at a low cost.

Alternative (Higher Welfare) Systems

A smaller number of broilers live in alternative, higher-welfare systems. These systems give birds more space and use slower-growing broiler breeds. They may also have outdoor areas for the birds.

Birds in these systems are slaughtered at about 9 weeks. This is older than the 5-7 weeks for fast-growing birds in intensive systems.

| Housing System | Stocking Density | Breed Type | Slaughter Age |

|---|---|---|---|

| Intensive (Industrial) Farming | 10,000-20,000 birds per house | Fast-growing strains | 5-7 weeks |

| Alternative (Higher Welfare) | Lower stocking density | Slower-growing breeds | Around 9 weeks |

“The choice between intensive and alternative broiler systems depends on factors such as market demands, consumer preferences, and the producer’s commitment to animal welfare.”

Broiler Chicken Nutrition and Feed

Broiler chickens are key to the poultry industry. They need a special diet to grow fast. Their food is high in energy and protein, given in pellets through machines. Some farms add whole grains to encourage natural foraging.

Feed costs are about 60% of broiler production costs. It’s vital to manage feed well. This ensures each chicken grows and develops properly.

Advancements in Broiler Nutrition

The broiler industry has made big strides in feed and nutrition. From 1957 to 2001, there were huge gains in growth, liveability, and feed conversion. This shows the industry’s dedication to getting better.

Research has focused on the development of the digestive system in chicks. Early nutrition is key for gut maturation and immune function. This knowledge helps producers improve their feeding methods.

Whole Grain Feeding in Broilers

- Studies have shown the benefits of whole grains in broiler diets. They help with digestive tract development and nutrient use.

- Whole-grain feeding encourages natural foraging. It also helps maintain a healthy gut microflora in broiler chickens.

- Looking into the metabolizable energy and nutrient utilization of grains like wheat, sorghum, and maize has improved feed formulations.

The broiler industry keeps looking for new ways to feed and nourish chickens. This focus ensures the production of high-quality meat efficiently and sustainably.

Growth and Development Stages

The broiler chicken lifecycle has two main phases: the brooding phase and the rearing phase. These stages are key to the chickens’ growth and development. They help the chickens reach the right weight for market.

Brooding Phase

The brooding phase lasts from 10-14 days after hatching. Growers must care for the chicks during this time. They need to keep the temperature, humidity, and environment right for the chicks’ health and growth.

Chick starter-grower feed should have at least 18 percent protein. This helps the chicks grow well during this phase.

Rearing Phase

After the brooding phase, the chickens enter the rearing phase. They grow and develop until they are ready for slaughter, usually at 5-7 weeks. During this time, their environment, nutrition, and health are managed closely.

Between weeks 5-15, the chicks need a starter-grower feed with 18 percent protein. This supports their growth.

As they near the end of the rearing phase, they might start on layer feed. Layer feed has about 16 percent protein and 3.25 percent calcium. This prepares them for egg production.

Birds usually start laying eggs at 18 weeks. Their best egg-laying time is around 25 weeks.

The rearing phase is the longest and most important part of a broiler chicken’s life. Growers must carefully manage the birds’ environment, nutrition, and health. This ensures they reach the right weight efficiently.

Flock Thinning and Catching

When broiler chickens get close to their final weight, some farms thin their flock. This means taking out some birds, usually the lighter females, to give the rest more room to grow. This thinning can stress the birds and make them more likely to get sick.

After thinning, the remaining chickens are caught and taken to the slaughterhouse. This is called broiler catching. Chickens are caught at night to reduce stress and keep them safe during this important time.

Industry data shows that about 20 to 25 percent of broiler chickens die each year. Good management and care during thinning and catching are key to keeping the birds healthy and reducing losses.

To help the remaining birds adjust well, farmers follow certain steps:

- They watch the birds’ weight and growth closely to know when to thin the flock.

- They use special teams and tools to catch the birds gently and quickly.

- They give the remaining birds enough rest and time to recover after thinning.

- They keep strict biosecurity to stop diseases from spreading.

By following these best practices, farmers can make the thinning and catching process better. This helps keep the birds healthy and boosts the farm’s productivity and efficiency.

Biosecurity and Disease Prevention

Broiler chickens are key to the poultry industry, but face many diseases. To keep the flock safe, farmers use a detailed biosecurity plan. This plan helps prevent disease outbreaks and keeps the broiler farm and poultry biosecurity strong.

Common Broiler Chicken Diseases

Broiler diseases like Newcastle disease, infectious bronchitis, and coccidiosis are big threats. These diseases can harm broiler flocks badly. To fight these, broiler chicks get vaccinated early. This gives them a strong defense against these common diseases.

Biosecurity Measures on Broiler Farms

Broiler farms take many steps to stay safe. These steps include:

- Limiting who can enter the farm and making sure visitors and workers clean up

- Cleaning and disinfecting everything thoroughly

- Watching the birds closely for any signs of sickness

By following these poultry biosecurity steps, farmers can lower disease risks. This helps keep their farms productive and profitable.

“Effective biosecurity is the cornerstone of a healthy, thriving broiler flock. By investing in comprehensive disease prevention measures, we can protect our birds and ensure the long-term sustainability of the poultry industry.”

Broiler Processing and Slaughtering

Broiler chickens are ready for slaughter when they reach 5-7 weeks old. They are then caught, crated, and taken to the slaughterhouse. There, they are processed into the chicken products we buy and eat.

The process starts with stunning the birds to make them pain-free. They are then quickly killed and have their feathers plucked. Next, their insides are removed to keep the meat clean and ready for more steps.

After processing, the chickens can become whole birds, chicken parts, or ground chicken. These items are then packaged and sent to stores and restaurants. We buy them as fresh, frozen, or value-added chicken products.

| Metric | Value |

|---|---|

| Broiler chickens accounted for an average of 67% of all poultry sector sales in the U.S. from 2013-2022 | 67% |

| Chicken eggs represented an average of 22% of poultry sales during the same period | 22% |

| Turkeys accounted for 11% of poultry sales | 11% |

| Total poultry sector sales in 2022 reached $76.9 billion | $76.9 billion |

| Broiler sales saw a 60% increase in 2022 | 60% |

The broiler processing and slaughtering industry is key to meeting the demand for chicken. It uses new technologies and follows strict food safety rules. This ensures we get high-quality chicken that meets our varied tastes.

Environmental Impact and Sustainability

The broiler chicken industry is a big part of global food production. But it also has a big environmental impact. It creates waste like manure and litter, and also greenhouse gases. These can harm the environment. But the industry is working hard to make farming more sustainable.

Waste Management in Broiler Production

Broiler farms use many ways to handle their waste. They manage litter, compost, and dispose of manure carefully. These steps help reduce the harm to the environment.

Sustainable Broiler Farming Practices

The industry is also looking into new, green farming methods. They’re using solar and wind power to run their farms. They’re also trying to use waste products, like manure, as fertilizers. This helps cut down on waste and pollution.

| Sustainable Broiler Farming Practices | Benefits |

|---|---|

| Renewable Energy Adoption | Reduces greenhouse gas emissions and reliance on non-renewable energy sources |

| Circular Economy Principles | Repurposes waste products, minimizing overall waste generation |

| Improved Waste Management | Reduces pollution and contamination risks associated with broiler waste |

By adopting these green farming practices, the industry aims to lessen its environmental footprint. This will make broiler chicken production more sustainable.

Future Trends and Innovations

The broiler industry is always changing. This is because of what people want, new technology, and the need to be kinder to animals and the planet. As we look ahead, new trends and ideas are coming up. They are changing how broiler chickens are raised.

One big trend is the growth of slower-growing broiler breeds. These birds grow at a pace that feels more natural. This is what some people want because they care about animal welfare and want food that’s better for the planet. Also, using on-farm hatching systems is becoming more common. This means fewer chicks have to travel, which is better for the animals and the environment.

There’s also a push towards using precision farming. This includes things like heat exchangers and systems that cut down on air pollution. The goal is to use resources better and make broiler farming more efficient. The industry is also looking into other protein sources, like plant-based or cultured meat. This is to meet the growing need for food that’s good for the planet.

| Innovation | Description | Potential Impact |

|---|---|---|

| Slower-growing broiler breeds | Development of broiler breeds that grow at a more natural pace | Improved animal welfare and consumer preferences for sustainable poultry |

| On-farm hatching systems | Reducing the need for chick transportation by hatching on the farm | Improved animal welfare and reduced environmental impact |

| Precision farming technologies | Using technologies like heat exchangers and emission minimizers to optimize resource use and reduce environmental impact | Improved efficiency, reduced air emissions, and enhanced sustainability |

| Alternative protein sources | Exploring plant-based or cultured meat to diversify the protein supply | Addressing consumer demand for sustainable protein options |

The broiler industry is evolving fast. Trends and innovations are leading the way. They focus on making life better for animals, being kinder to the planet, and meeting what people want.

The broiler chicken lifecycle is complex, from hatch to market-ready birds. The broiler industry has grown a lot over the years. This growth is due to consumer demand, better breeding and nutrition, and the push for sustainability and animal welfare.

Most broiler chickens are raised in intensive farming systems. But a smaller number are raised in better systems that care more for their welfare.

Research and innovation keep improving broiler production. They aim to solve environmental issues and meet the world’s growing need for affordable, sustainable chicken meat. Studies have found important factors that affect how well broiler chickens hatch.

These factors include eggshell thickness, the thickness of the mammillary layer, and egg weight. They also looked at how eggs with hairline cracks affect hatchability and how they increase embryonic mortality.

The broiler chicken lifecycle is always changing. The industry must find a balance between efficient production and treating animals and the environment well. By using the latest in breeding, nutrition, and housing, the industry can meet global demand. It can do so while keeping animal welfare and environmental care at the highest levels.